Like most people, you have probably lost count of the number of perfectly pristine-looking shoes you have tossed out simply because the rubber soles are cracked. In addition to the expense and hassle of replacing footwear, it is also harmful to our environment. According to the U.S. Department of the Interior, 300 million pairs of shoes end up in landfills each year, where they can take 30 to 40 years to decompose. Now, thanks to a revolutionary self-healing 3-D printed rubber material, fractured shoe soles may be a thing of the past.

The magical polymer is the brainchild of researchers at the University of Southern California's (USC) Viterbi School of Engineering and the University of Connecticut (UConn). The team, led by USC Assistant Professor Qiming Wang and UConn Assistant Professor Ying Li, created it through a process called photopolymerization, which uses light to solidify the liquid resin used to create 3-D printed plastic. The researchers found that adding the right proportion of oxidizer to the liquid resin allowed the 3-D polymer to heal without slowing down the hardening process.

"When we gradually increase the oxidant, the self-healing behavior becomes stronger, but the photopolymerization behavior becomes weaker," explained Wang. "There is competition between these two behaviors. And eventually, we found the ratio that can enable both high self-healing and relatively rapid photopolymerization."

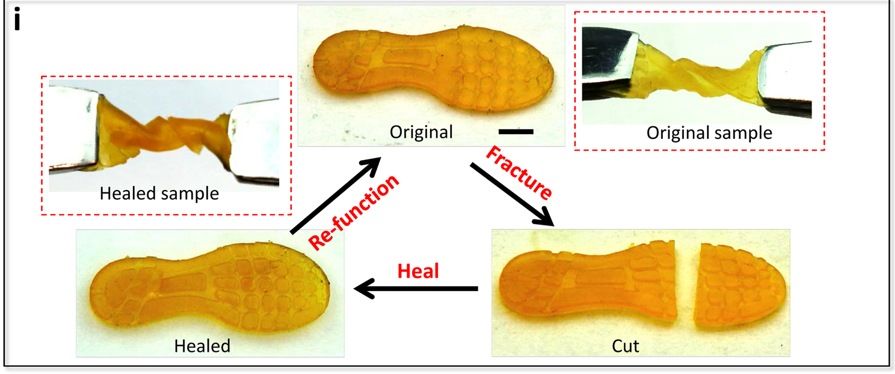

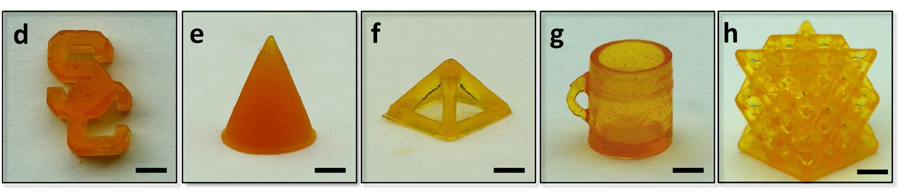

Using the technique, the researchers were able to 3-D print a 17.5-millimeter square in just 5 seconds and entire objects in only about 20 minutes. Even more impressive, when the plastic was sliced in half and subjected to temperatures of about 140 degrees Fahrenheit (60 degrees Celsius), it completely self-repaired in just two short hours!

The team, who published their findings in the journal NPG Asia Materials on February 1, 2019, state that the repair time can be reduced by increasing the room temperature. "If you just put a broken shoe on a bench at room temperature, the rubber will heal itself in six to eight hours," Wang said. "If you apply heat, at maybe 140°F (60°C), that accelerates the healing process to about two hours."

Given the material's tremendous potential, it is not surprising to hear that Wang and his team have been approached by several shoe manufacturers eager to be the first to deploy the technology, which is still in the early stages. Once perfected, the scientists also hope to apply the technique to hard plastics that can be used to create self-healing toys, electronics, vehicle parts, and, if Wang has his way, even tires. Now, if someone could only come up with an automatic solution to erase the scuffs and stains that seem to magically appear on our favorite shoes, life would be perfect.

Resources: rubbernews.com, the engineer.co.uk,endgadget.com